Abstract

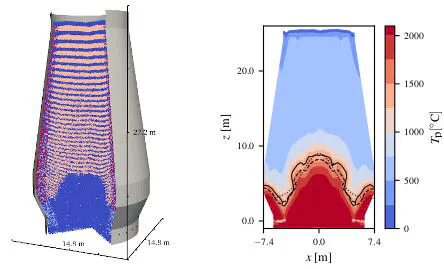

Hot, reacting, moving particle beds as found in blast furnaces comprise a wide range of spatial and temporal scales. We present an approach that combines models for granular motion, interfacial mass, momentum and heat transfer as well as heterogeneous multi-step reactions efficiently. Although they correspond to vastly different scales, long-term investigations built upon data from discrete-element simulations become feasible. The strategy was first applied to 0.5 kg hematite reducing to iron under a CO atmosphere, where the most relevant reaction parameters were obtained from optimization towards experimental data. Then, we studied a 3D, full-scale blast furnace and its approach towards the thermo-chemical steady state over the course of 20 h. The framework may be easily extended, which will allow for realistic simulations of moving particle beds over process-relevant durations. It has the potential to create digital twins so that different reactor types can be optimized and novel designs explored.

Publication

Chemical Engineering Science

Blast furnaces, still the dominant type of steel-making reactor, are difficult to simulate because of the vastly different time scales involved. While stiff grains and fast gas flow dictate small time steps, large-scale material transport and chemical conversion take place over the course of hours. To bridge this massive gap, we employed a simple time-extrapolation technique built upon detailed CFD-DEM data from which we obtained the granular velocity field. To cover long durations, we replaced solid, interacting particles with non-interacting counterparts that followed the prescribed streamlines while exchanging heat and mass with the surrounding gas flow. This allowed us to use much larger time steps and describe the evolution of a full-scale blast furnace towards its thermo-chemical equilibrium at comparatively little numerical costs.